Here is a way to upgrade your 1210 standard platter. The basic idea is to strip away the rubber from the underside of the platter and replace it with a material that is a better at damping. An excellent material for this is Dynamat.

This is the process:

1. Stripping the rubber underside;

2. Cleaning the surface;

3. Cutting the Dynamat to the correct size;

4. Applying the dynamat to the underside of the platter.

Advantages of the DIY method - YMMV;

- You will get a better platter - it is really good;

- Satisfaction in doing it yourself;

- No hassle with transferring the inside of your existing platter;

- If you like the look of the original platter;

- If you wish to keep the strobe;

- The DIY platter will weigh about the same as the original;.

This weight point is important in my opinion. The 1210 was built to certain specifications including strength and torque of the motor. The 1210 motor of course will have tolerance outside the platter weight range, but there is no need to add drag to the motor and weight to the bearing if it is not necessary.

http://i1279.photobucket.com/albums/...ps7b0a465b.jpg

Dynamat is a dense butyl. I first came across it when I outfitted my car with an Alpine Stereo System. It is great at deadening sound and vibration. I build PCs and when I can't get an acoustically damped case I use Dynamat.

The tools I used for for stripping the rubber off from under the turntable were a good quality paring knife and a large screwdriver. You could use two screwdrivers. A broad cold chisel might help as well. If you do it carefully it could come off in one piece.

Basically what you are doing is starting around the outside edge of the rubber and working the knife underneath to get a purchase for the screwdriver. When you have enough loosened rubber you can use your hands to pull some more loose. The good news is that you will find that the glue or bonding agent has been imperfectly applied (all the more reason to do the job!) and some of the rubber will come off rather easily. The bad news is that it will require considerable strength and patience to pull it all off.

You can see here that there there are large places where the bonding agent has not connected with the rubber under-mat. Clearly the rubber mat does nothing for the structural integrity of the platter.

After you have removed the rubber you will see that there are bits of residue rubber and glue left on the underside of the platter. Keep chipping away at it with the paring knife. Your patience will be rewarded. What that is mostly done you must then clean it. I used Acetone, Synthetic Steel Wool and rubber gloves. You can use whatever cleaning method; only be sure you take off 100% of the rubber.

This is what it should look like after you have striped and cleaned it completely.

Before you begin do your quantity surveying to ensure you have enough dynamat. Cut off a corner and have a play. Try cutting it with scissors and a craft knife & metal ruler to get a feel of what you are working with. Also apply some to a spare surface, again to get a feel of what you are doing.

This is the underside of a sheet of Dynamat. The paper peels off revealing the sticky black butyl. Here you can see the outlines of what I am going to cut. The outside will be cut with large scissors and the small holes with nail scissors. Nail scissors are curved at the tip. It is especially handy to have the Dynamat cold when you are doing fine cutting. Prior to cutting and peeling you should also make one or two templates. In the pic of the tools you will see a couple of pale green cutouts. The one with the finger holes is particularly useful. What the template is, is a mock-up of the dynamat you are going to place into the inside of the platter.

When it fits you know that you have got your measurements spot on. If it does not fit then you work out where you went wrong and make another. Once your template it 100% you then place it over the paper-side of your dynamat and see if that matches. In so doing you effectively have a 'dry-run' and you will know with 100% confidence that the dynamat you have cut out will fit exactly.

Here you can see I am nearly finished. Two points to note. One is that you will see the large circle of Dynamat placed into the platter has been cut in two. It did not have to be cut in two and in a previous effort I have laid down one single circle of Dynamat with a large hole in the middle and the two smaller finger-lift holes. That is an OK method. The advantages of cutting it in two are twofold. First, it is a little easier to apply. It is important to avoid airholes or we get the same stuff-up in the original platter. Second, the diameter of the magnet is smaller than the metal ring around it. So a better fit can be obtained by placing it down in two parts. One tip: do a last checking for size by putting down your Dynamat before stripping off the paper backing. The second point to note is the thin strips of Dynamat that around the edge. I have done this by cutting 8 thin pieces and inserting them one by one. One will be 7 or 7.5 mm wide. The other will be 8.5 or 9 mm wide. You will get your measurements with a ruler to get the diameter and do the pi thing.

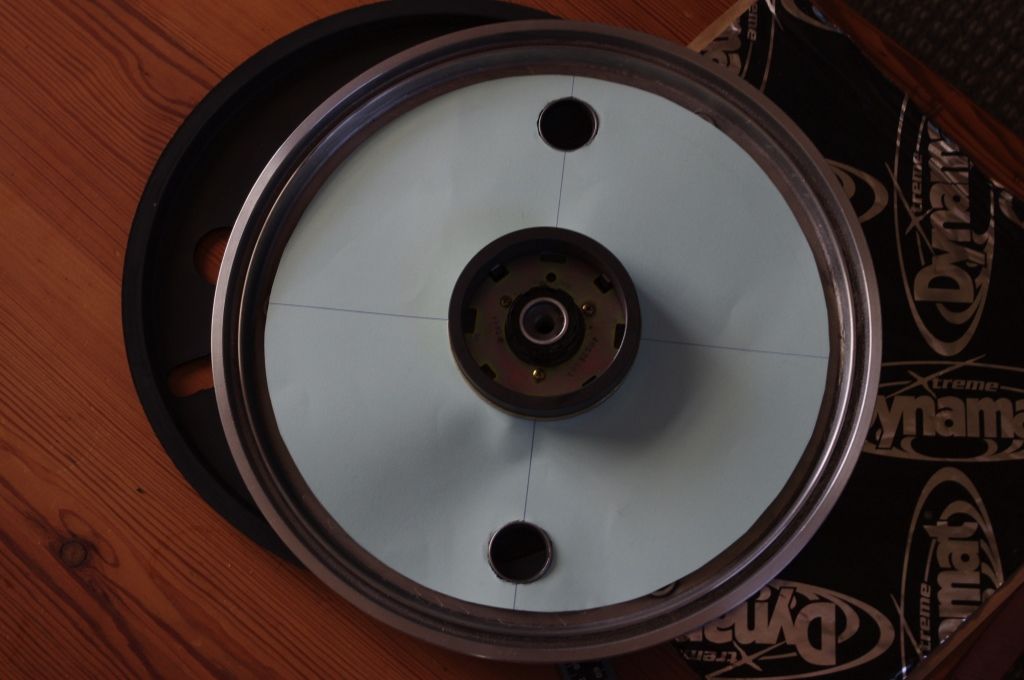

Here is the finished product.

Dynamat is a great product. It is excellent at Sound Damping. See http://www.dynamat.com/technical_spe...at_xtreme.html for specifications.

It is fairly easy to cut to shape. (Hint 1 - use a knife and straight-edge in preference to scissors where possible, Hint 2 - it cuts a little more tidily if it has cooled in the fridge first.)

It bonds to the metal surface very well. See http://www.dynamat.com/technical_ins...tallation.html for instructions on applying it.

It weighs about the same as the rubber it replaces.

The original platter is not good. If you hold it by the magnet and tap it with a spoon you can hear it rings like a gong. Incidentally If you do the same test after you have stripped the rubber it resonates about twice as long. so I estimate that the rubber damping is about 50% effective ... pretty useless. The same tapping test after the Dynamat is in place produces no ringing. It is almost as dead as Monty Python's Parrot. In terms of sound difference it worked really well and I felt the base tightened up nicely.

Reply With Quote

Reply With Quote