I think almost everybody who tried a high quality external regulated psu appreciated the improvements in sound quality it made over the Technics stock supply , I was very impressed with the PH PR3G3HD-21 diy based supply, it was certainly worth the effort imo.

A few of us have been discussing why not try taking things further ? The plan was to install a pair of 21v high quality regs inside the Technics to supply the motor and its drive circuitry separate from the rest of the circuitry instead of the shared voltage from the external regulated psu . We then increase the output of the external regged supply to allow for the voltage drop needed for the new internal regulation to work.

Paul Hynes designs the best regulation I've come across so was pleased to find he can supply the PR3 modules without the rectifier , this makes them about half size of the full AC input module and makes them a good fit inside the Technics.

The PR3DC-21 DC input modules are suited for the standard 1200/1210 platter , the PR3DCHD-21 are higher current and suited for both standard platter and Mike New platter .

Heres what I've done so far

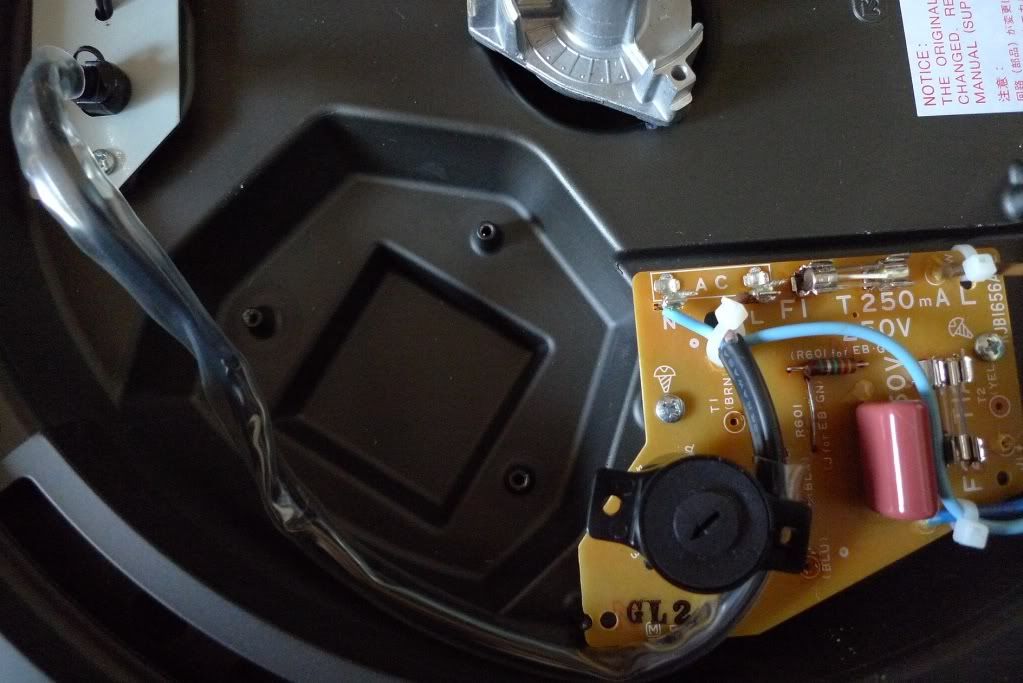

Inside the stock 1210

Transformer + shield removed, pcb removed

Bottom of pcb after removal , be careful removing the wired plug in sockets and all the screws

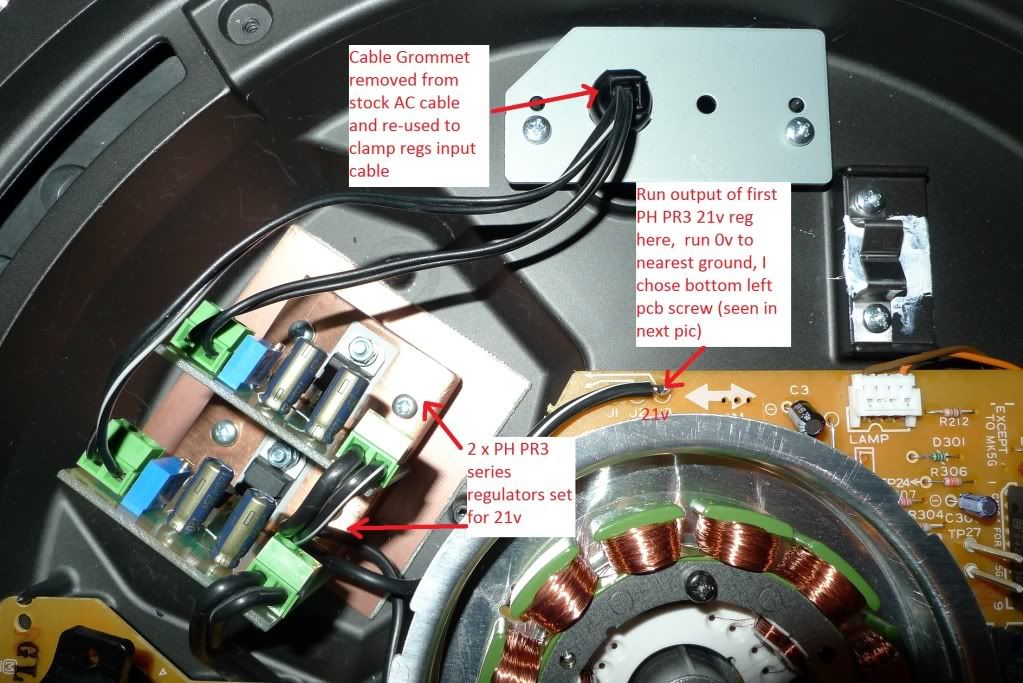

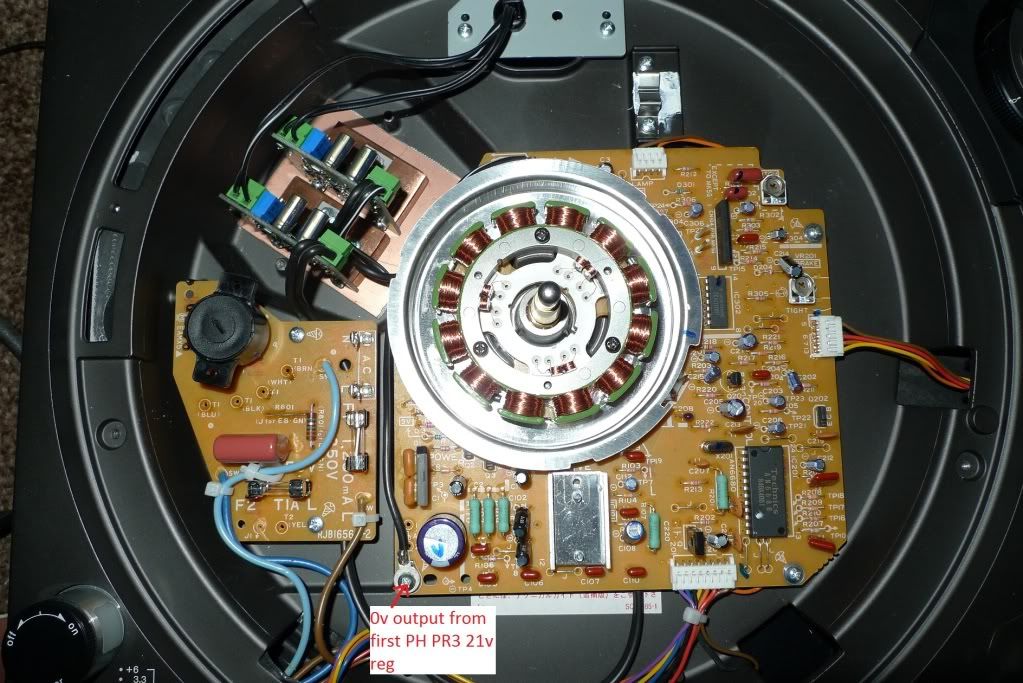

Separate Paul Hynes PR3DCHD-21 series regulators adjusted for 21v output fitted in the space where the stock transformer sat , I bolted both regulators to a piece of copper clad board to keep them together as a temp fix, some form of mounting plate would be better long term.

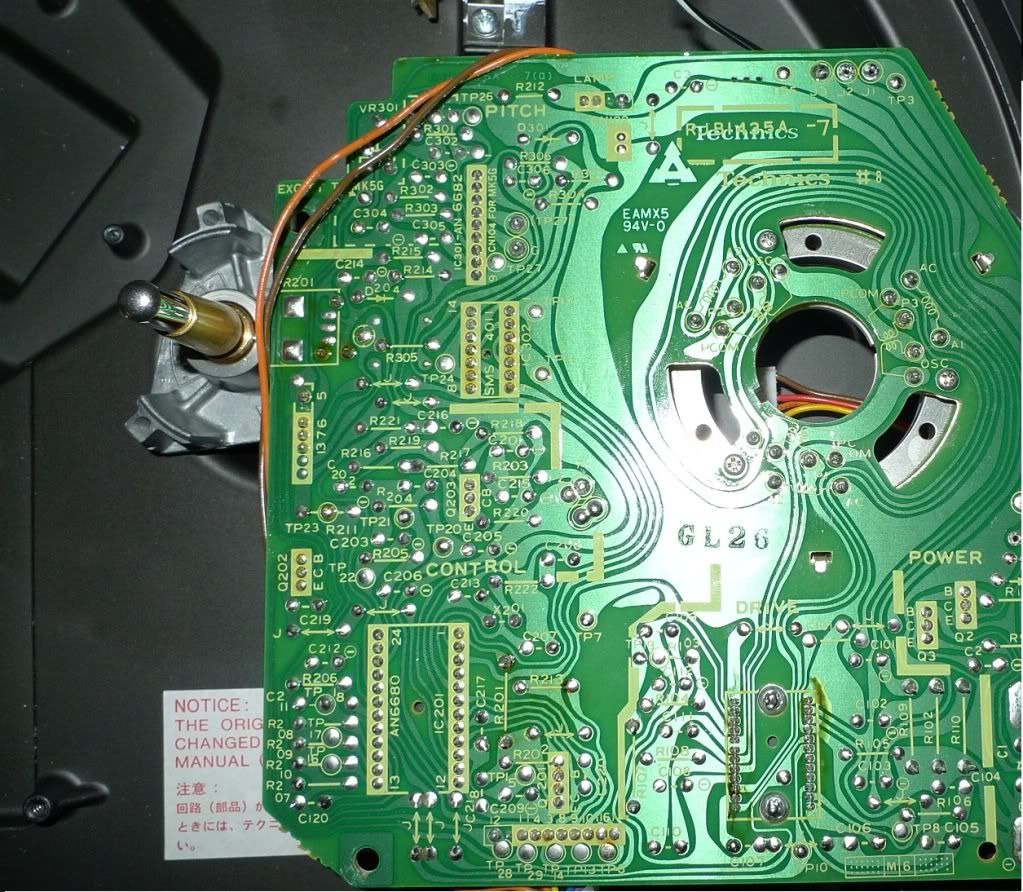

The output transistor (part of stock regulator ) was also disconnected and removed.

The top 21v PR3DCHD-21 regulator supplies the main (top half ) of the pcb , the bottom 21v PR3DCHD-21 regulator now supplies the 21v bottom half (motor and its circuitry )

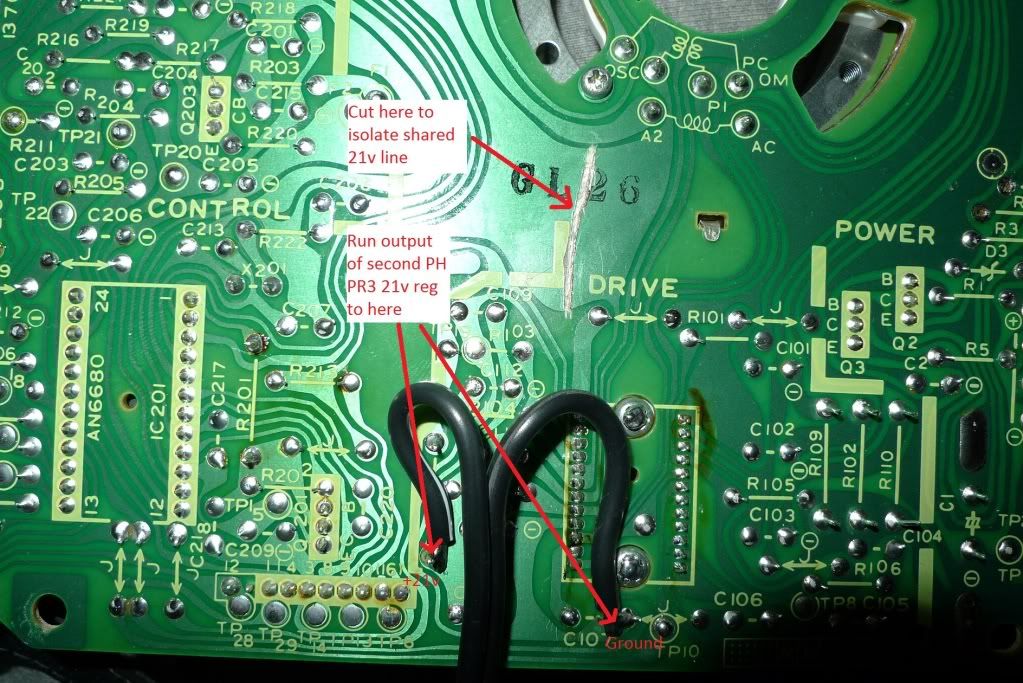

Bottom of pcb showing track cut isolating the second part of circuit supplying motor and its circuitry , the black cable is from the output of second 21v PR3DCHD-21

Top view showing pcb refitted , the regs in place, wiring etc

The external regulated psu used now has to have its output adjusted higher to around 27v to give enough headroom for the newly fitted 1210 internal regs. I built another PR3/5 based psu using the higher current PR3ACHD-27 (pics added later) and fitted a transformer with higher rated secondary voltages (the one I fitted originally only had 18v secondarys ) .

The PR5 psu's simply need a small adjustment and don't require any component or transformer change. I also tried an external regulated psu based LM1084 which worked too, definitely not as good as the Paul Hynes module though.

Going from the stock 1210 psu to the diy external one using the PR3G3HD-21 module http://theartofsound.net/forum/showthread.php?t=6043 improved the sound in all area's to my ears, infact tbh I was very impressed ! A thick veil was lifted and had reduced distortion, definitely tighter more tuneful bass and brought out more details in the high's. The whole thing sounded more musical and toe tapping.

With the upgraded internal separate regs fed from PR3DCHD-27 there was noticeable improvements, not as large as going from the stock psu to the external one but I did notice a further layer of background muck (best way to describe it) removed, a little smoother in the high's and decrease in sibilance I used to hear on some recordings, bass gained a little more depth whilst remaining tight. All in all very nice.

Swapping the external psu using the PR3DCHD-27 to the one based around CRC feeding a LM1084 also gave good results but to my ears the bass lost some impact and speed, it seemed to loose some of that wow factor it had with the PR3DCHD-27.

Seems the main regged psu still has some influence even when the 1210 is using separate internal regs, I need to try out and compare a few more things yet so will update as soon as I can.

I got all the price details for the regs from Paul for those interested

PR3AC-21/27 standard AC input module £100

PR3DC-21 standard DC input module £80

PR3ACHD-21/27 higher current AC input module £120

PR3DCHD-21 higher current DC input module £100

Postage

Insured carriage and packing for 3 modules is £10 in the UK, £14 in Europe and £20 to the rest of the world.

Most other stuff like cable, case, transformer etc can be found from Maplin, RS and Farnell

Added 07/01/2011

A few pics of the external psu

Paul Hynes PR3ACHD-27 High current module

Its all discrete! these are much more complex than a simple LM317

Transformer and PR3ACHD-27 fitted to the cases base plate, the additional heatsink added is quite chunky, I fitted this for a reason

I wanted to test this psu with a Virtue Sensation amp too which is classT based.

Cables soldered onto the pcb pads bottom of pcb underneath the sockets

Not the prettiest case but is the best I could get hold of, The Hammond ones wasn't quite big enough this time. I used 4pin lock plug and sockets to allow comparing DC cables later , sorting the cabling out properly will be done last

Reply With Quote

Reply With Quote

Isaac Bashevis Singer

Isaac Bashevis Singer