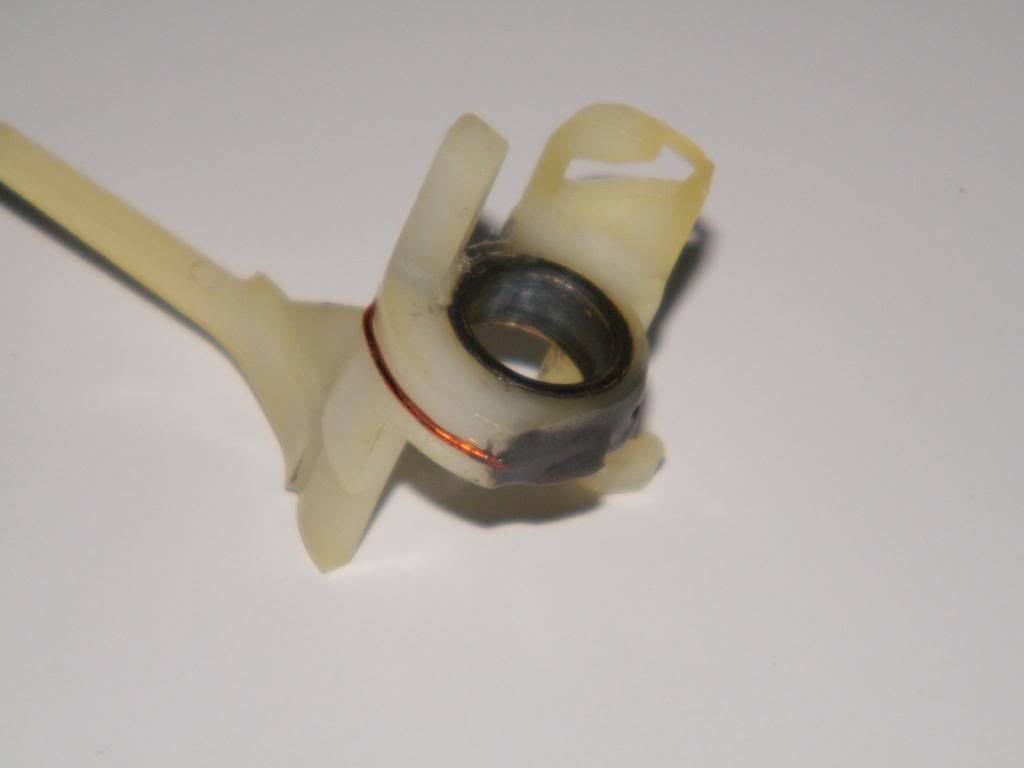

Hey Folks, just got myself a 1210 , but have the opportunity to get my hands on a Technics SL-1400 mk2. Anybody got any impressions. The cueing lever is no longer functioning. Apparently this is common enough.

I love the aesthetics of it.

One thing I can't manage to get a pic of is the feet. Are they screw in feet like the 1210.

Reply With Quote

Reply With Quote Nathan

Nathan

Originally Posted by phonomac

Originally Posted by phonomac