Recently had a TT100 in for a service. Work done:

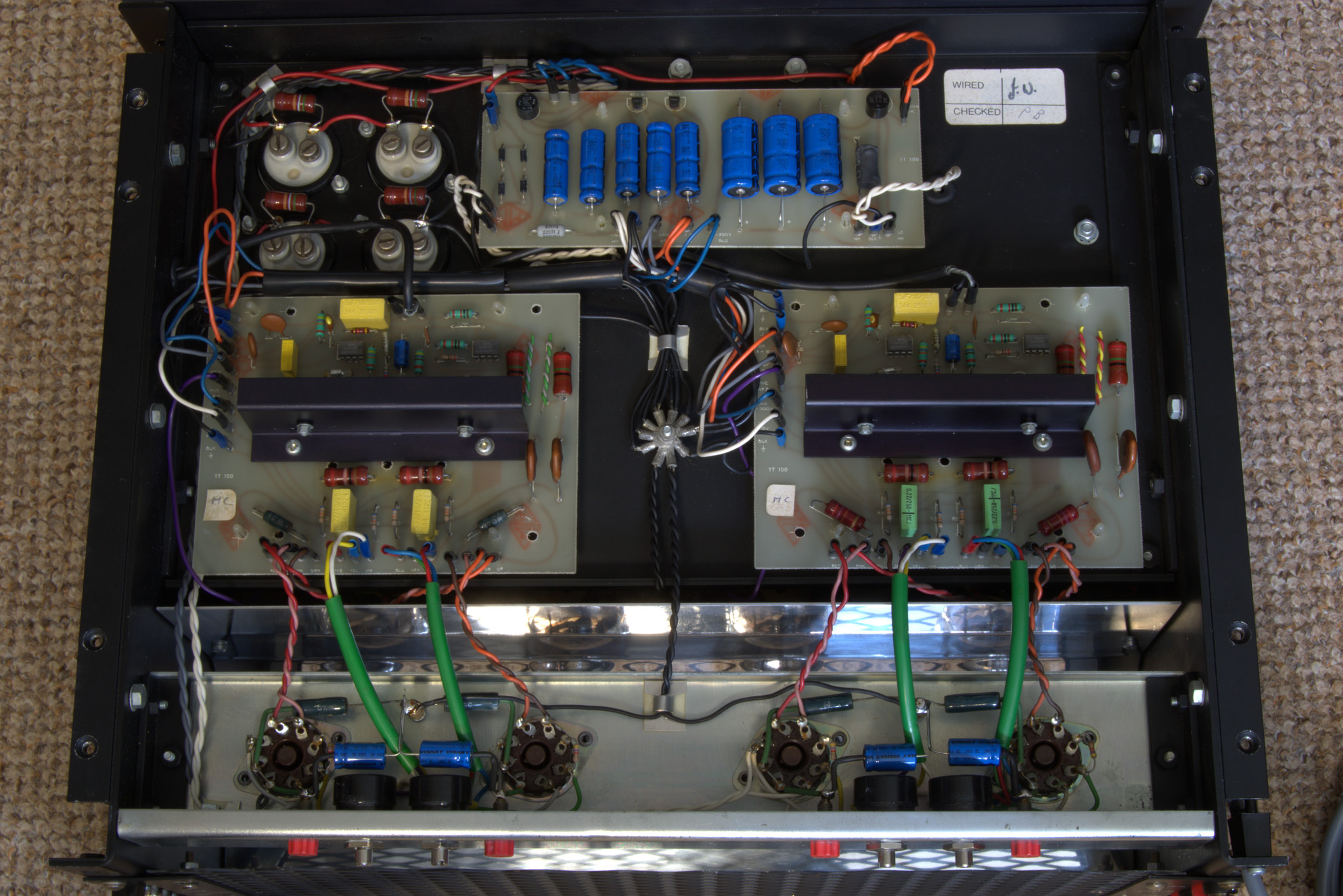

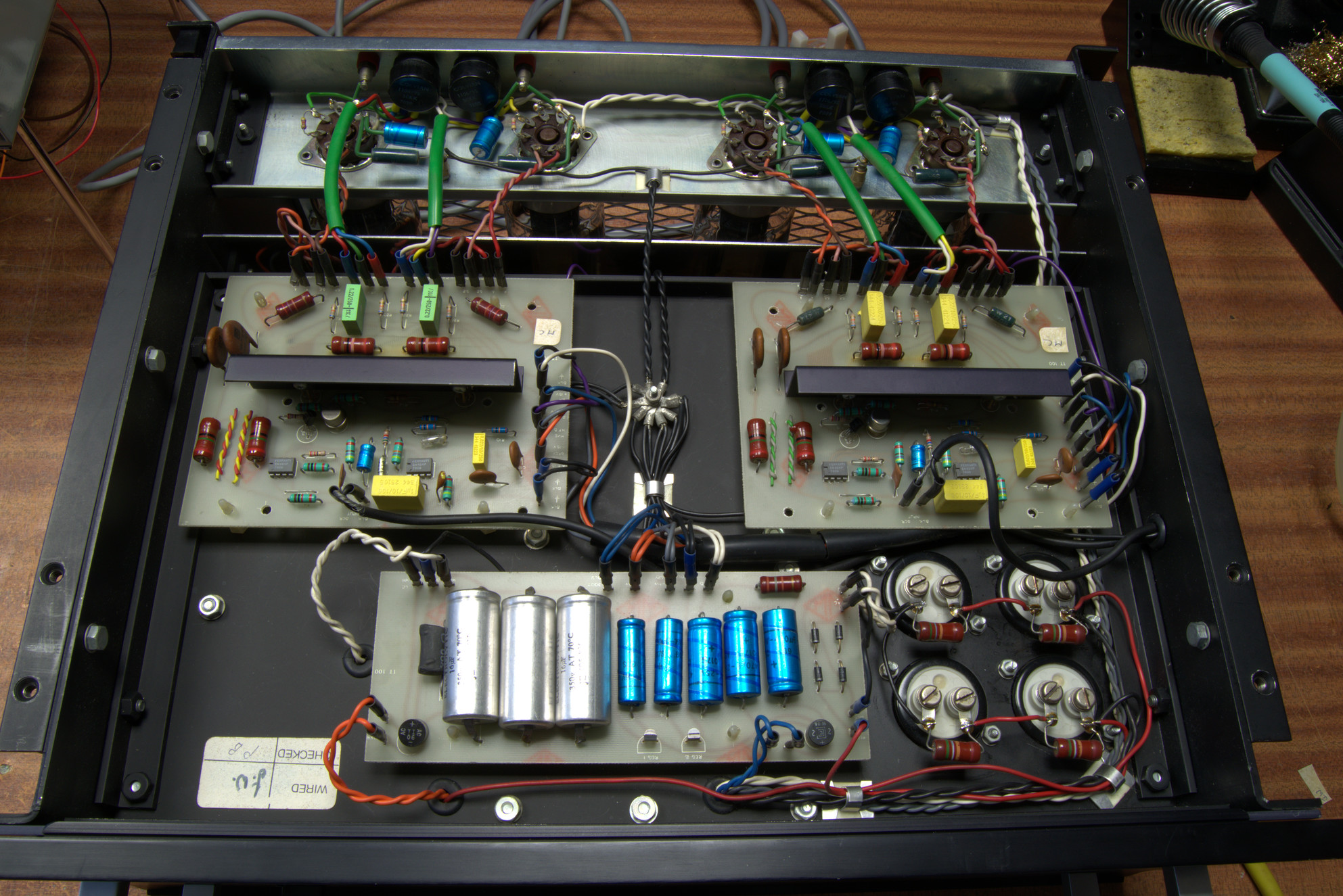

- Replaced leaky electrolytics. Most of the blue Phillips types were showing physical signs of chemical leakage and no doubt electrically leaky too. To be honest after I spotted the physical signs I just opted to change the lot. The main PSU cans had been done to quite a good standard previously by someone so left as is.

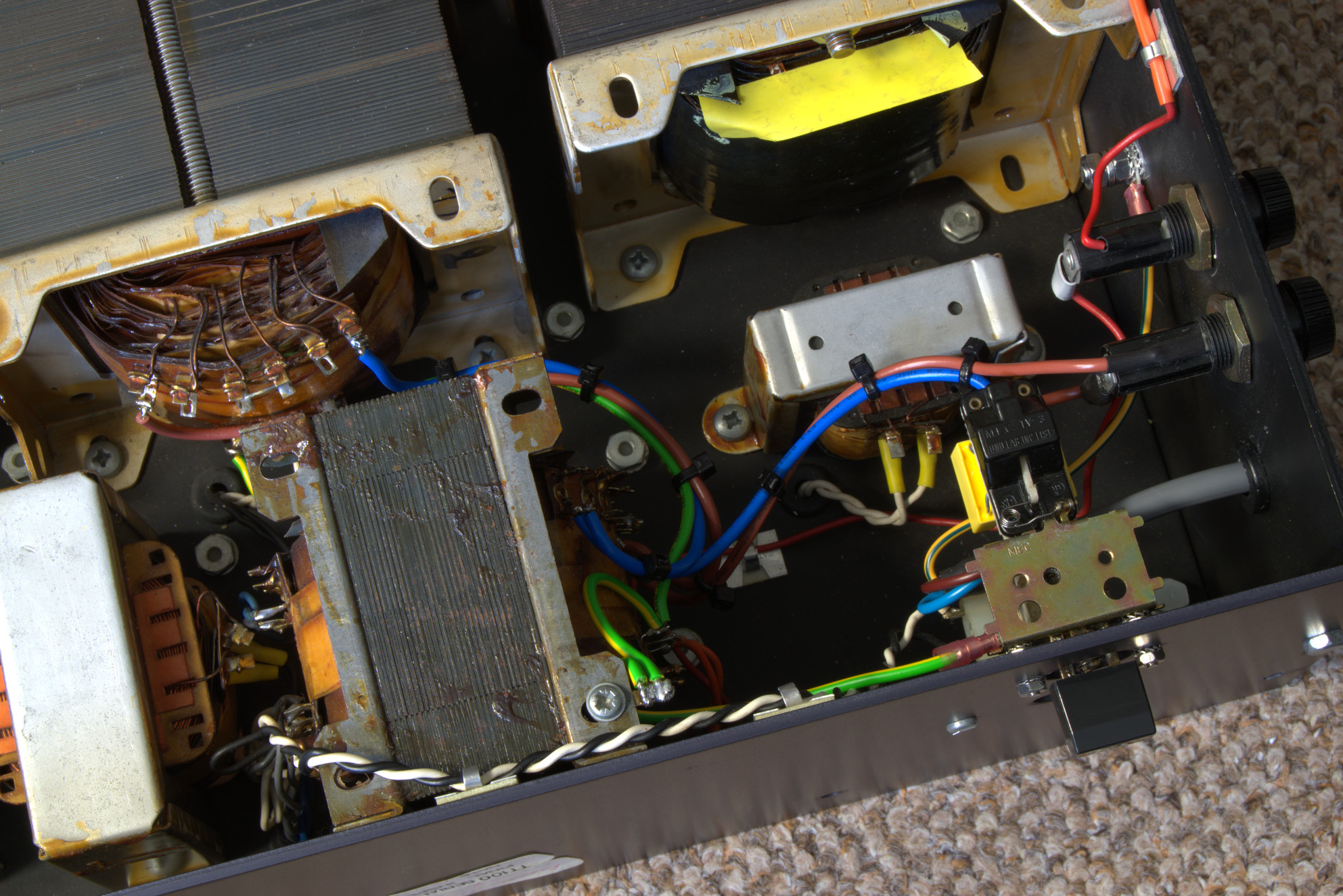

- New mains flex and clamping with far better PE to chassis connection

- New internal mains wiring.

- Repaired mains fuser holder (was repairable without becoming hazardous, plus it's inside the amp anyway)

- New output valves and re-biased.

- Simple mod to underside of the main PCBs to breath an L-R earth loop issue that apparently is an oversight with these amps. Luckily the PCB layout lends itself to an easy fix.

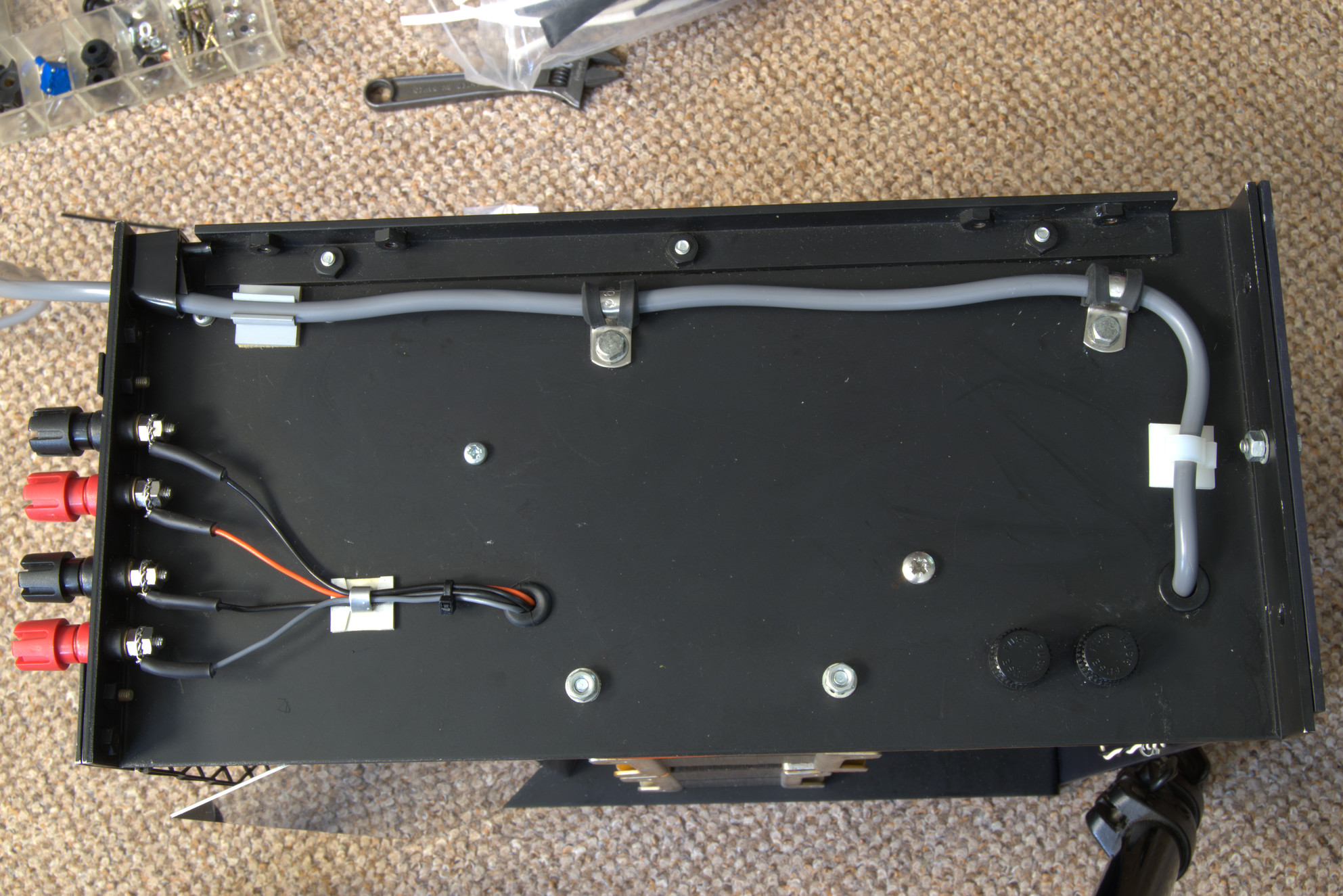

- New cliff binding posts to fit the keyed holes in the amp (to replace some cheap ones someone had fitted, which to be fair was done to a good standard but the plastic threads on them had stripped).

Good as new and ready for another few decades!

Reply With Quote

Reply With Quote