Originally Posted by

Ianmac

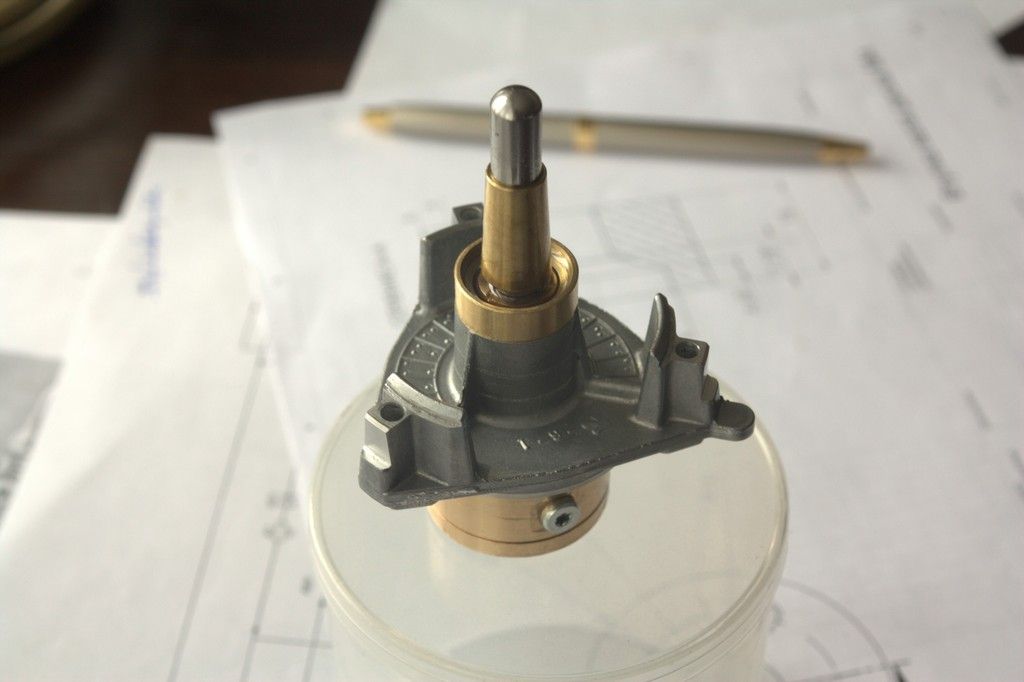

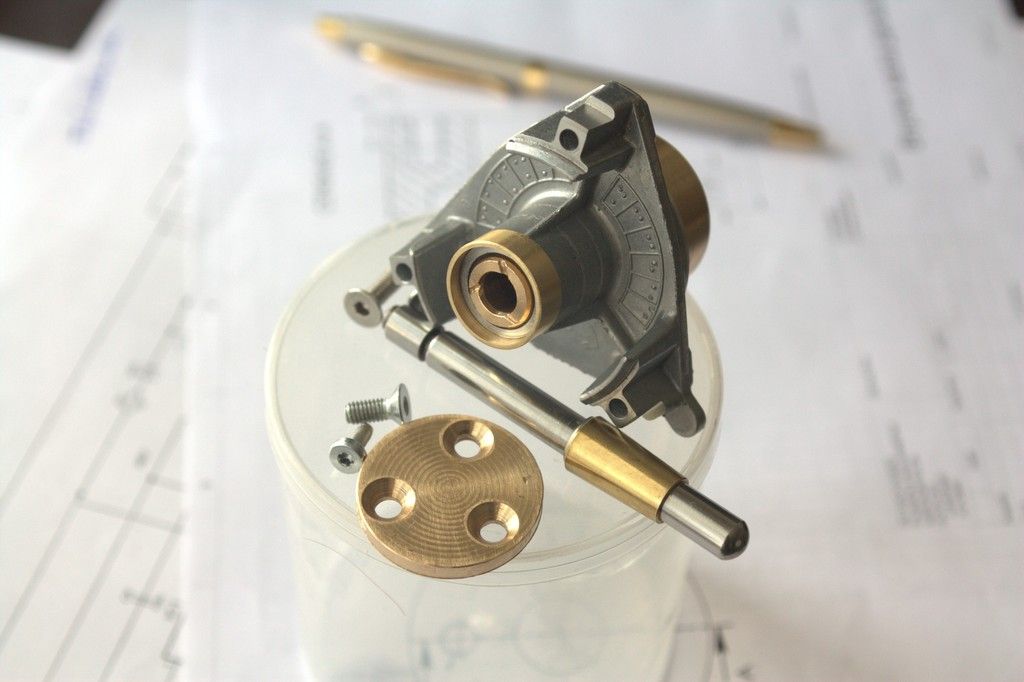

I did drill a 1mm vent hole in my bearing to allow for any mechanical/ oil volume change with temperature change in the oil bath. Maybe overkill on my part but it doesmake the insertion of the bearing shaft easier.

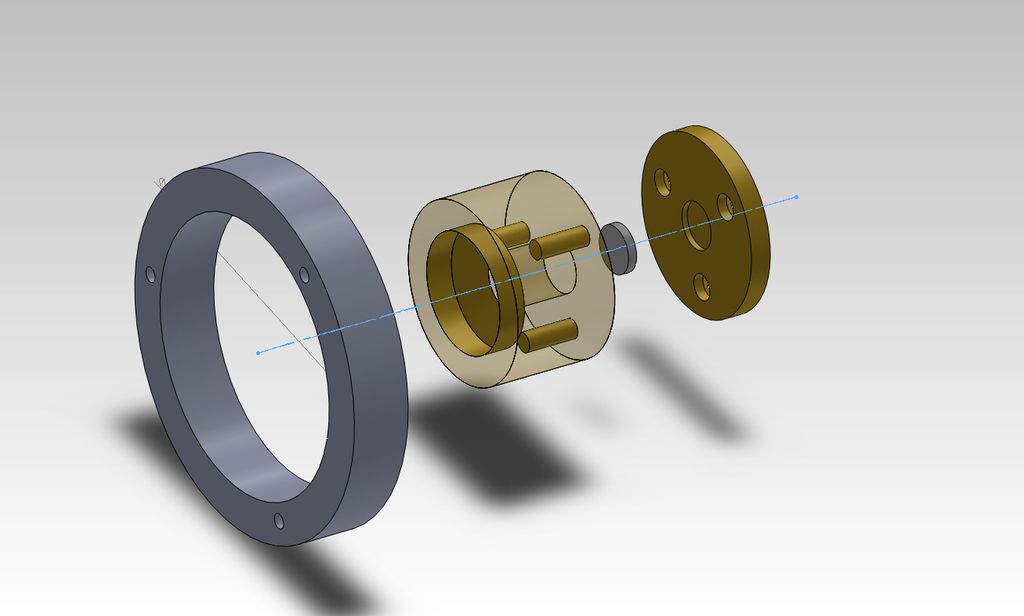

I think your solution is better than mine. Don't sure about temperature volume changes, but initial oil filling should be more convinient with vertical hole. My design of this hole near to useless.

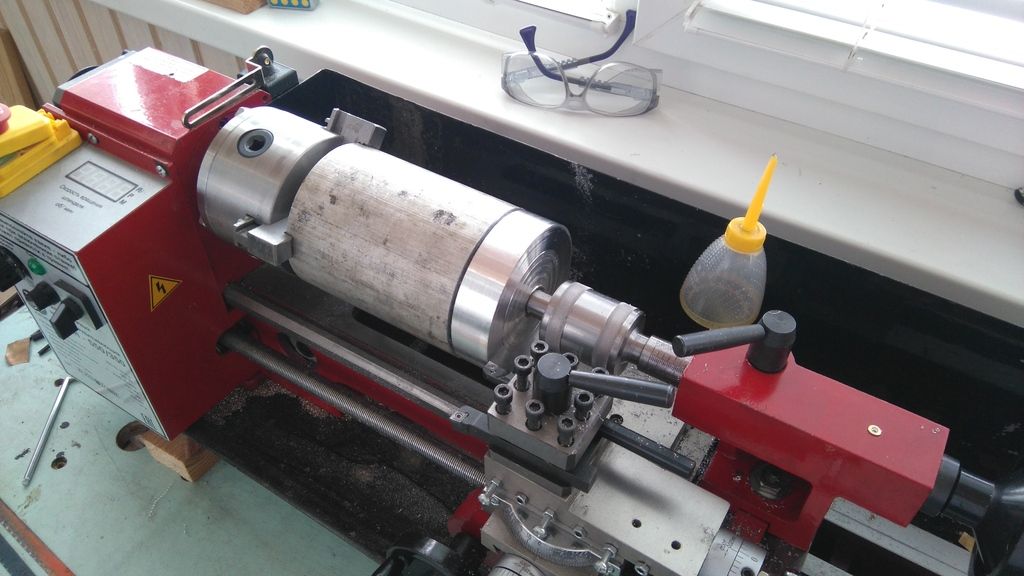

Get the lathe running again and try an under slung counter weight ?

Ianmac

Never think about counterweight upgrade, do you have some ideas? I equipped my lathe by QCTP and it ready to fight

Analog: Technics SL-1200MkII (RB300 tonearm, external PSU, separated power supply for all stages, improved bearing), MC Goldring Eroica LX, custom SUT 1:10, Balanced input J-FET DIY phonostage

Digital: Cubietruck (headless Debian server, i2s output, external masterclock from DAC), content on HDD. DAC: Lynx D29v4 (Altera FPGA digital stream separator, 2*AD1853, 2*3 OP42 LPF)

PA: DIY composite amplifier YES-3, schematic by Gennady Bragin

Acoustic: DIY floorstanding 3-way SB Acoustics

Reply With Quote

Reply With Quote

Originally Posted by Ianmac

Originally Posted by Ianmac