Hi All.

Have joined for some advice on a project that i'm about to undertake. I have 2 technics 1200 mk2's from back in the 90's when i used to DJ. They look their age and have been through life with menow I'm old settled down and only use one. But it could do with looking better! So i managed to source a new faceplate that i'm going to try and swap out on the deck that's not in use. I've been recommended this form for advice. So any threads that are worth me reading?

I have of course watched Viper franks you tube videos here: https://www.youtube.com/watch?v=CDYgjwdQ55s these have at least given me the confidence to try and do itIt doesn't look that fiddly and my plug isn't moulded on anyway (never was) so the soldering bit can be skipped too!

On question is where should i get some more of that heat compound from?

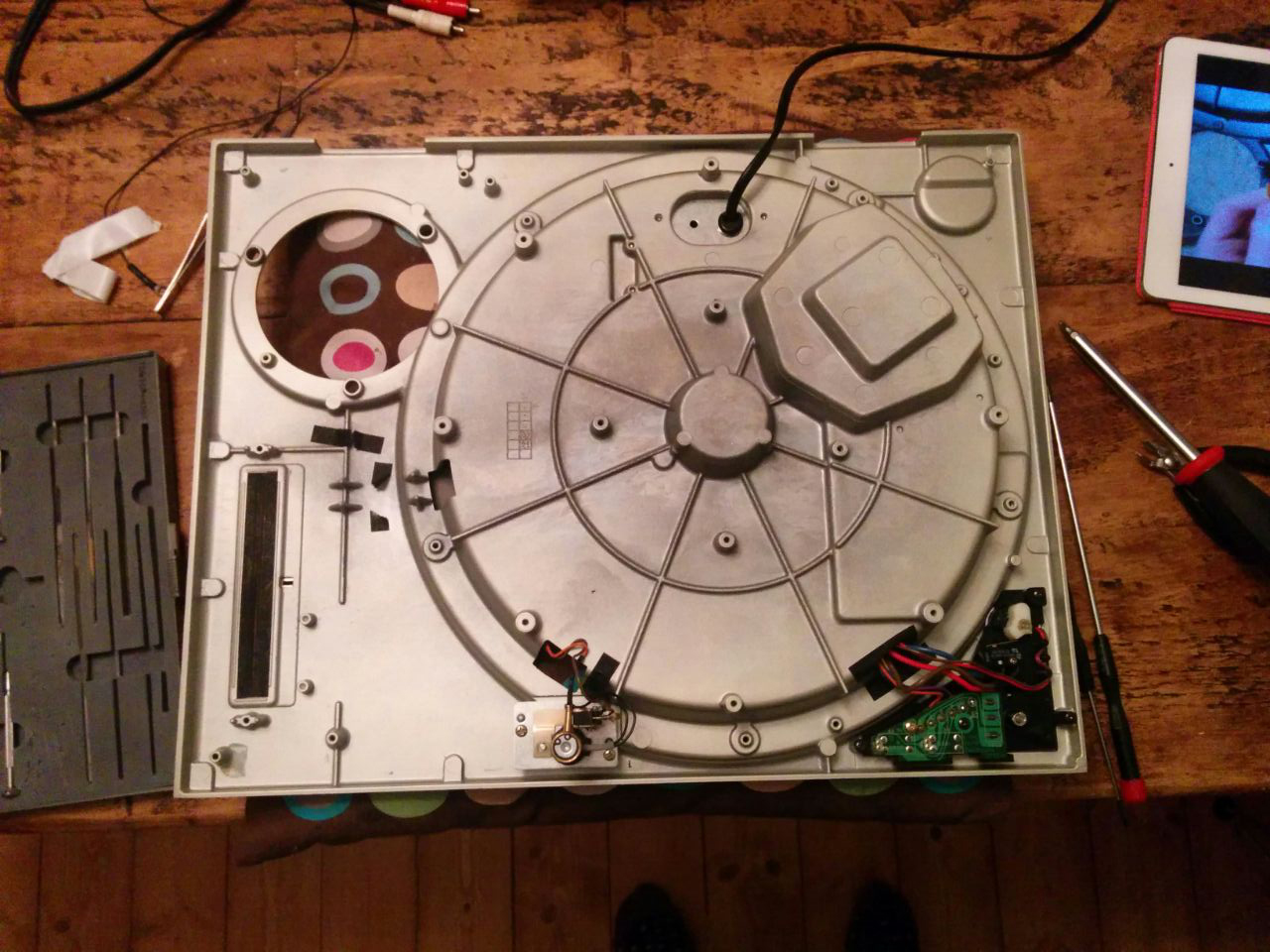

New faceplate! :

Cheers for any advice.

Rob.

Reply With Quote

Reply With Quote Originally Posted by Bigbob666

Originally Posted by Bigbob666