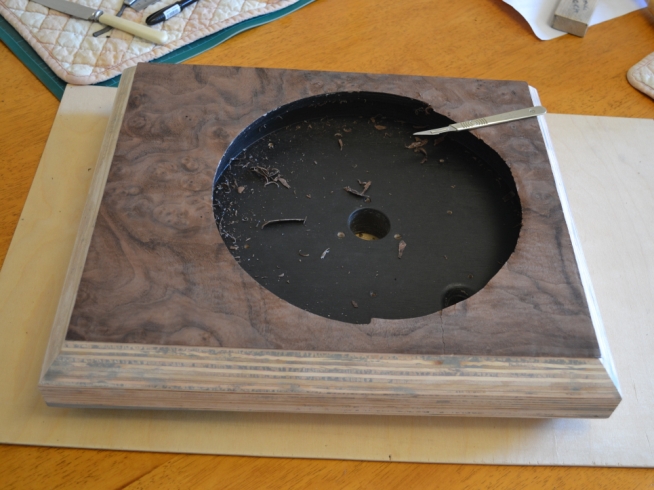

Started the veneering process, it's American Black Burr Walnut.

Spent ages thinking about how the pieces would be cut from the sheet. I ended up making paper templates and laying them out on the sheet, just to make sure they would all fit butted up together, this was essential to get a continuous grain pattern over the surfaces. When it was all laid out I only had 50mm extra veneer on the length and 5mm on the width so no room for error. I found the Burr much harder to work with than ordinary Walnut, it's brittle and cracks easily.

Got a few more pieces on, the pattern running across the panels seems to work well so it was worth the effort.

I previously used iron on veneer that had the hot melt glue already applied to the back, it was a creamy yellow in colour and I found it difficult to disguise the joint lines on edges, especially noticeable on darker woods.

This time I used plain veneer and a separate sheet of clear EVA hot melt, that came on a backing sheet. You tack it to the back of the veneer with an iron, peel off the backing and iron it on to the job. The film of glue is a lot thinner and combined with the clear colour makes a neater joint.

The wood grain looks drab at the moment, eventually it will get a coat of Danish oil. which will really lift the colour.

Reply With Quote

Reply With Quote

Originally Posted by Qwin

Originally Posted by Qwin