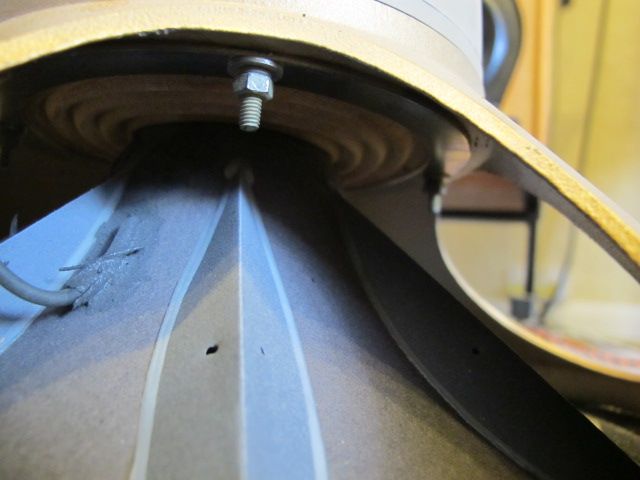

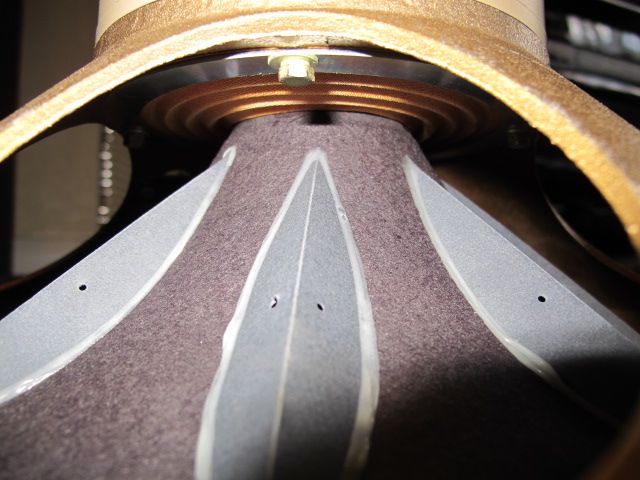

Strange that one driver has bolts retaining the spider, whilst the other appears to have studs and nuts, even though the serial numbers are reasonably close. Tannoy were consistant in their inconsistancy!

Take great care unbolting the spiders. It's easy for washers to get drawn into the magnet gap and extremely difficult to get them out again.

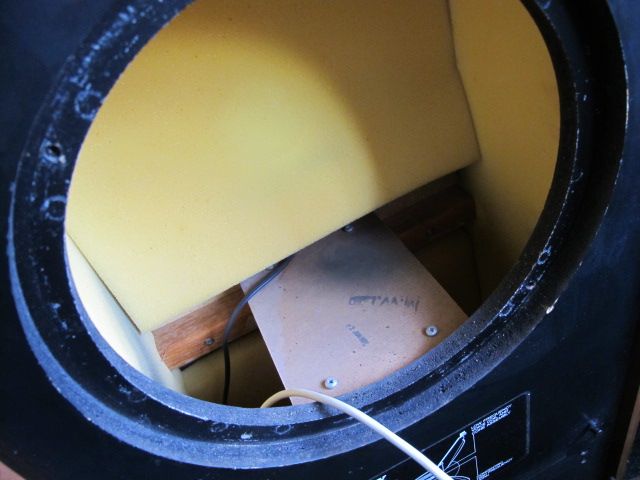

The screw fixing for the cone roll surrounds should be visible once the foam strips are pulled out. Probably easiest initially just to cut through the remains of the old surrounds as I did prior to lifting the cone out.

It is impossible for anything digital to sound analogue, because it isn't analogue!

Originally Posted by Audio Al

Originally Posted by Audio Al

Reply With Quote

Reply With Quote