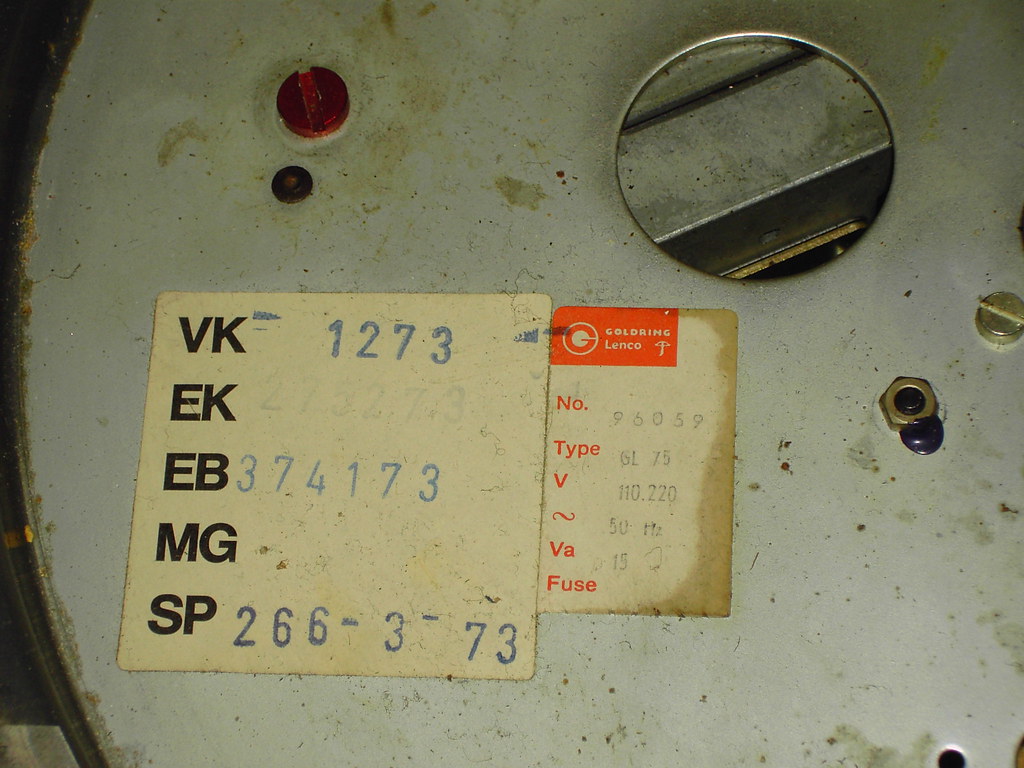

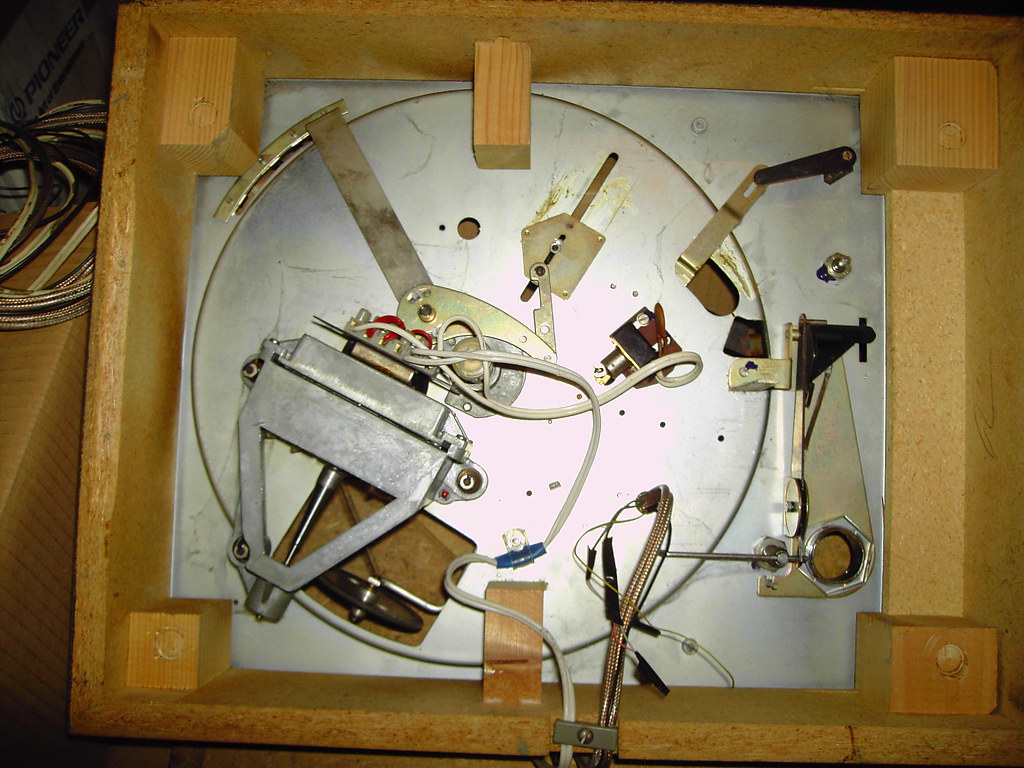

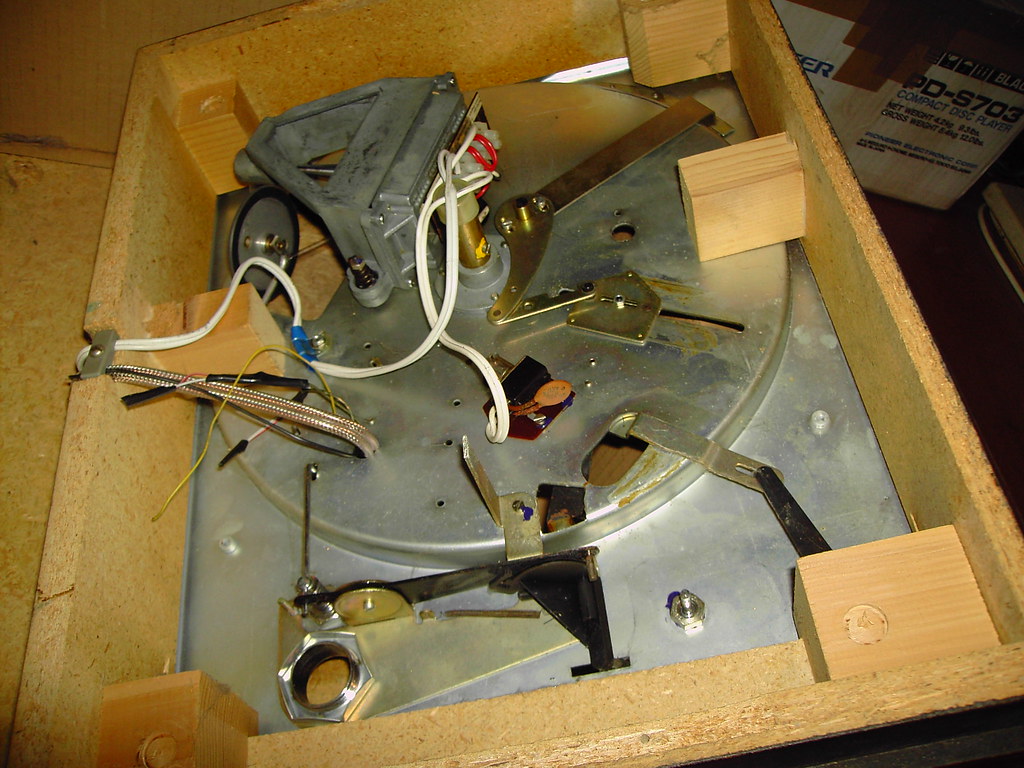

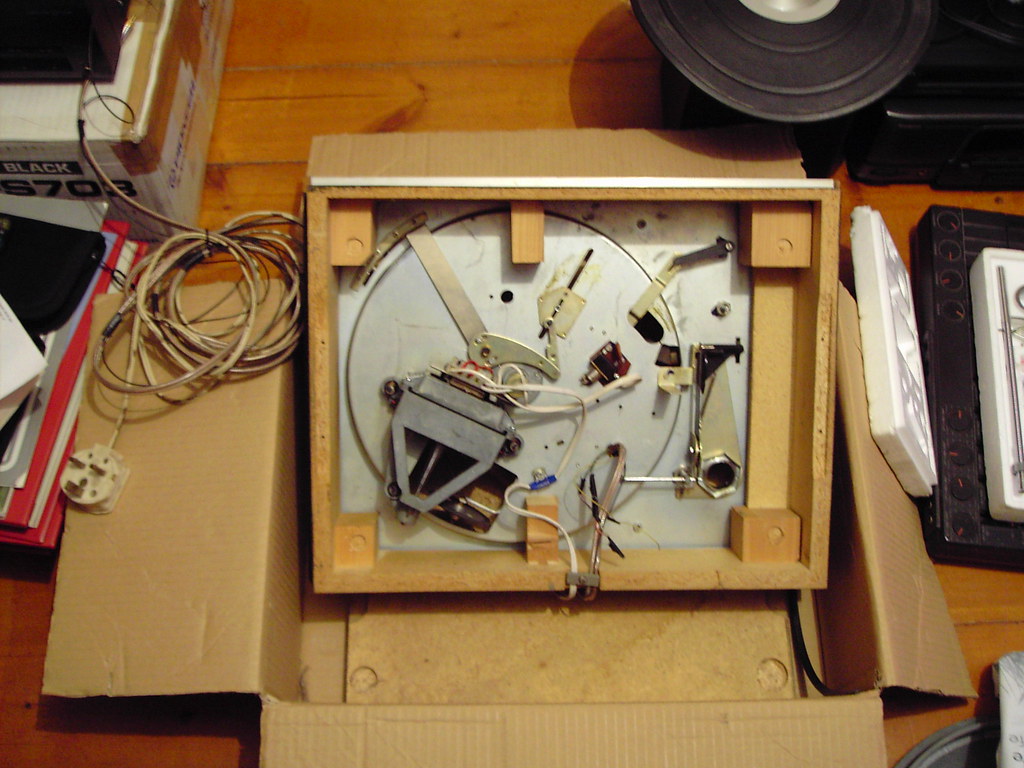

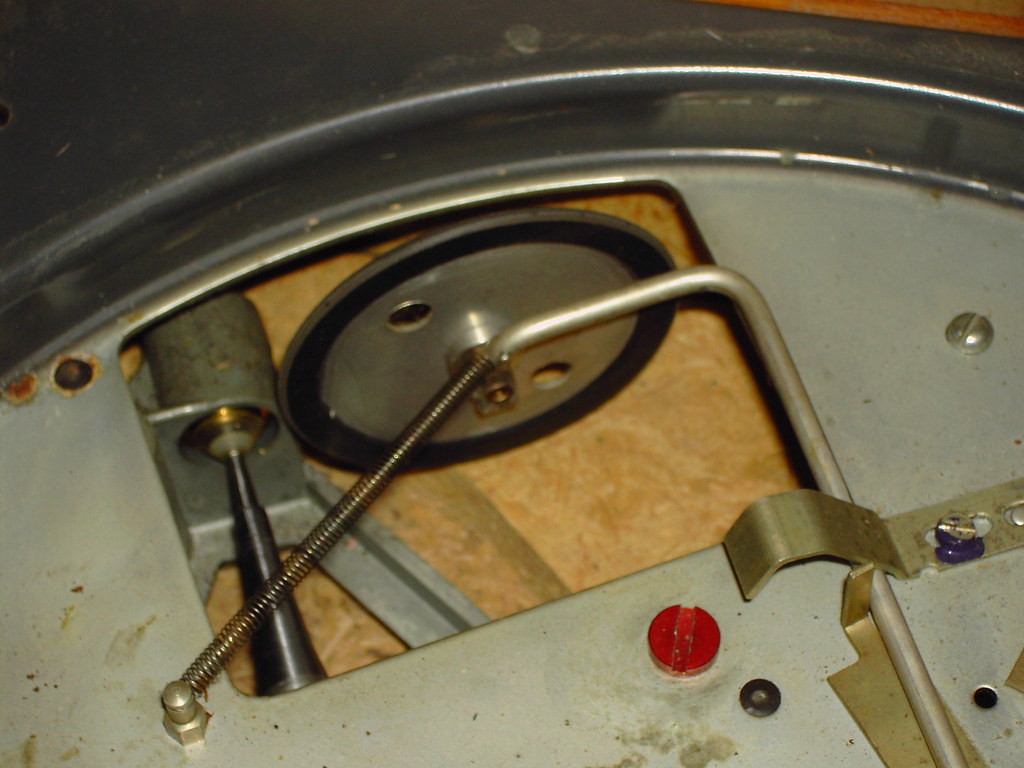

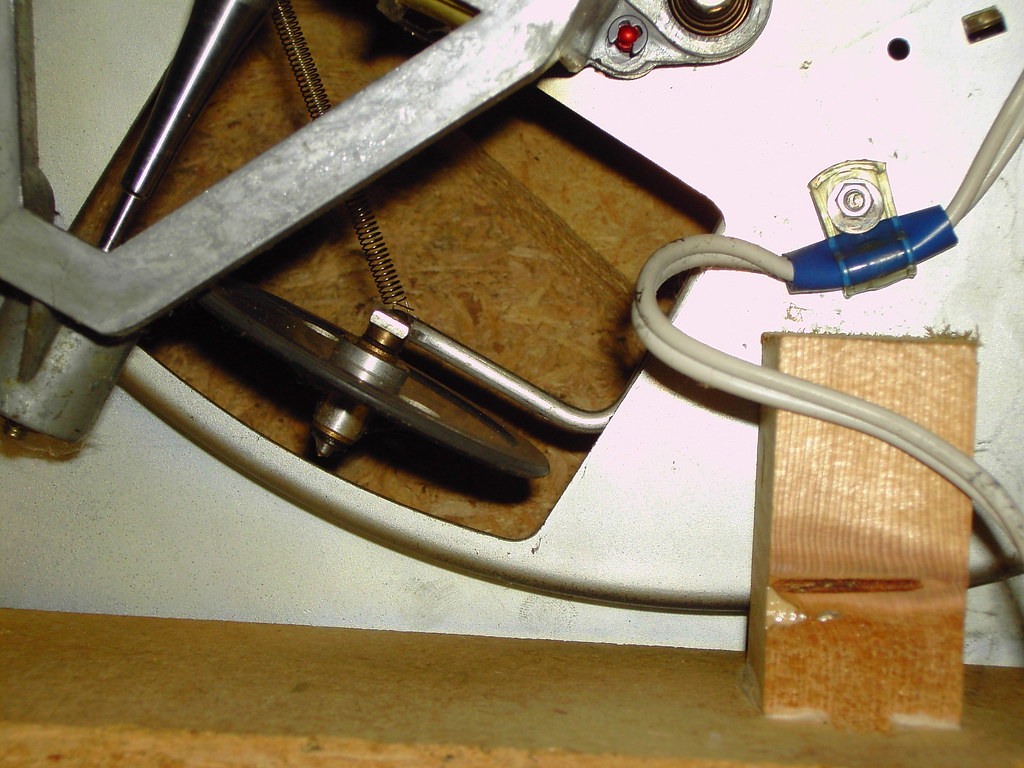

The arm internal wires are fairly heavy gauge as tonearm wires go, but should still be serviceable ? The external wires to the amp have been done already. Don't forget to slacken the red motor transit screws and ensure the motor floats freely as best as possible.

The idler looks like a mid period one. The early ones had a solid plastic (?) inner and the later ones had four or five holes cut out of the inner. Carbon Tetrachloride was suggested to clean the motor pulley, underside of platter and the rubber tyre, although I've used switch cleaner solvent with no worries. Make sure to clean the under edge of the platter too to prevent the platter brake from squeaking loudly on switch-off....

Regarding arm alternatives - I wonder if one of the Notts Analogue ones could be made to fit the hole? The price would be prohibitive though I suspect. I still think the L75 arm could be breathed on to good effect and if the arm/cart resonance is "only" 8 Hz with a Shure M75-ED, then there are many good carts under a ton which the arm should safely handle I think..

Tear down these walls; Cut the ties that held me

Crying out at the top of my voice; Tell me now if you can hear me

But, I want to learn how to do this stuff, and no better way than the hard way. I'm hoping to call on the wealth of experience here and hoping you'll all be patient with my frequent very basic questions!

Reply With Quote

Reply With Quote